drive shaft coupling failure

Discussion Starter 1 Feb 7 2015. Up to 50 of damage to rotating equipment is directly related to misalignment.

Causes For Pump Coupling Failures How To Avoid Them Sintech Pumps

This is because with the passage of time the bearing seal cap can rust.

. Selecting the wrong coupling for the application shaft speed. Sometimes heat can even travel through a shaft and cause coupling failure. It is the compensating coupling with a backlash free and conformal torque transfer providing high torsional stiffness and a low moment of inertia.

Disc couplings are often the best solution with their all-steel design. Driveshaft Coupling Failure. The Two-Shaft raw water pump shaft couplings will wear and fail due to.

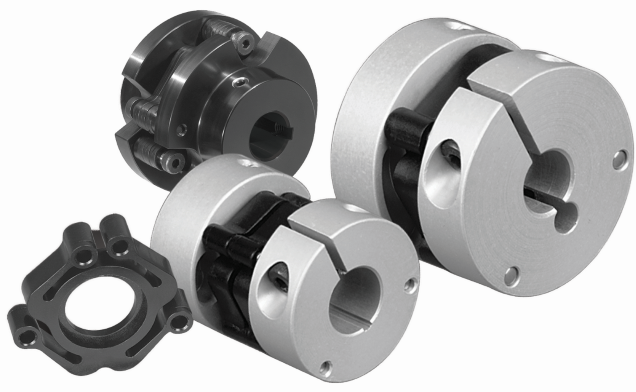

Coupling in the machine industry is interpreted as a part that connects two shafts together and is generally called. Of the two shafts. Among various mechanical parts the shaft coupling is one important part.

Drivers will lose control of their vehicle if the drive shafts failure occurs during high speed cornering. It is important to identify high ambient temperatures that may occur at the coupling. You may also hear sounds while the car is shuddering from the worn-out U-joint.

If the shaft is to be removed the gearbox oil will need to be drained first. If the U-joint of your drive shaft rotates too fast or fails to rotate then its a problem with your drive shaft. If the cushioned plate option is followed this is not necessary.

The life of the drive shaft is FuchsHenry 2001 Metal Fatigue in Engineering different for different duty cycle. A coupling is a mechanical element part that connects two shafts together to accurately transmit the power from the drive side to the driven side while absorbing the mounting error misalignment etc. At Crane Engineering we find the root cause of coupling failure ladders up to one of the following reasons.

One Piece Set Screw One Piece Clamp. Jump to Latest Follow 1 - 14 of 14 Posts. Youll need to have your drive shaft replaced because you cant drive your vehicle in this condition.

The main causes of magnetic failure are high temperatures vibration reverse magnetization etc so as one of the professional magnetic coupling manufacturers our magnetic coupling must run in a synchronous state. The failure may be coursed by improper installation excessive misalignment and poor coupling selection and so on. Joined Apr 20 2007 697 Posts.

All flexible shaft couplings are designed to allow for misalignment of one. A loose U-joint or bad center bearing within the driveshaft may cause the faltering acceleration. Shaft couplings are divided into two main groups as follows.

The gearbox is unbolted and supported as it is moved clear and can then be lifted clear for inspection on a bench. In such a case the vehicle can no longer be propelled and the. It is used to connect two perfectly aligned shafts.

Jaw-coupling inserts are also available in alternate materials that can withstand temperatures up to 480-deg F. Over all the cause for JohnWilley First Edition 2001. The types of shaft couplings are various.

Keyed Sleeve Coupling The sleeve coupling is the most straight forward type of rigid coupling also know as a muff couplingIt is a machined cylinder that joins two shafts usually a drive shaft and a driven shaftUsed when two shafts. 3 Early failure of the short-lived shaft bearings from age and use. 2 Abnormal wear caused by lack of lubricant packed in coupling.

Damage is usually felt on the drive shaft itself. Misalignment can be caused by improper installation of the pump and motor pipe strain even bent shafts. Either that or the u-joint itself is not stable.

Shaft misalignment can limit a machines performance cause excessive vibration high reaction loads and accelerated wear and often leads to premature equipment failure. If the drive shafts universal joint revolves very fast or cannot revolve then there is an issue with your shaft. The cap seals of the bearings could have rust on them.

The major failure occurred in drive shaft is due vibration torsional stress and bending stress was experienced by driveshaft due to the weight of the car or misalignment of journal bearing. B Clamp or split-muff or compression coupling and. But those different categories have one thing in common they are all backlash.

Failure to consider the couplings maximum safe operating speed during the design stage can quickly result in failure sometimes with tragic consequences. The shaft couplings will also need to be undone for the same reason. The magnetic coupling fails when the permanent magnets are demagnetized or lose their magnetism.

When the shaft begins to bear tension it may cause the hub to move away from the drive. Elimination of Failure Point The KWS one-piece drive shaft will not fail under fatigue or torsional loadingExpensive downtime is minimized creating a. Put in a new Dorman one and it has destroyed itself in just 2 months.

The main cause of drive shaft failure is the tension generated in the drive shaft. Fatigue failure of the drive shaft is due to overloading and 3 ASM metals handbook Fatigue and fracture vol. Although you may do quite well on the maintenance of couplings they can still fail sometimes.

A drive shaft driveshaft driving shaft tailshaft Australian English propeller shaft prop shaft or Cardan shaft after Girolamo Cardano is a component for transmitting mechanical power and torque and rotation usually used to connect other components of a drivetrain that cannot be connected directly because of distance or the need to allow for relative movement between them. Flexible Shaft Couplings can help prevent these issues by transmitting torque while compensating for parallel angular and axial misalignment between drive components. Excessive misalignment between joined shafts is one of the most common reasons for coupling failure due to the creation of loads that surpass the coupling specifications.

1 Normal torsional pulses generated as the impeller climbs over the pump cam. When the hub starts to be out of line with the shaft the drive will be damaged. Simplified Spiral Replacement Since the coupling faces are perpendicular to the product flow the spiral can be easily unbolted and removed vertically from the trough without disturbing the drive shaft and gear reducer.

A Sleeve or muff coupling. In order to improve coupling service life. Up to 8 cash back Experiencing a significant shudder when accelerating from low speed or a stopped position it can be another sign of failing driveshaft components.

Had to replace my factory rear driveshaft coupling recently has a few small cracks due to age. Following types of rigid coupling are important from the subject point of view.

Choosing A Reliable Conveyor Chain For Your Application In 2021 Conveyor Chain Broken Chain

About Shaft Couplings Nbk The Motion Control Components

Shaft Coupling What Is It How Is It Used Types Of Roles

What Is A Coupling How Does A Shaft Coupling Work Types Of Shaft Coupling

Laser Alignment On Site Laser Alignment Of Pumps And Motors Gear Units And Fans Coupling Misalignment Is One Of The Most Fr Alignment Electric Motor Mechanic

Pdf Analysis Of Ship Shaft Line Coupling Bolts Failure

Flexible Shaft Coupling Bc Series Oep Couplings Sleeve And Shear Pin

About Shaft Couplings Nbk The Motion Control Components

About Shaft Couplings Nbk The Motion Control Components

Control Flex Shaft Couplings Flexible Shaft Couplings

Parallel Misalignment Or Offset Top And Angular Misalignment Bottom Fire Protection System Mechanical Engineering Design Alignment

What Is Coupling Definition Types And Uses Engineering Choice

Why Is My Disc Coupling Slipping On The Shaft Youtube

Mechanical Power Transmission Training Mechanical Power Power Transmission

12 Reasons For Coupling Failure And How To Avoid Them Insight Acorn Industrial Services Ltd

Elastomer Shaft Coupling Download Scientific Diagram

Damaged Rubber Part Of Flexible Coupling Installed Between Main Engine Download Scientific Diagram

Flexible Shaft Couplings For High Temperature Applications

Shaft Coupling Definition Types Uses Working Principle Advantages Complete Guide Engineering Learn